CRACK REPAIR ADHESIVE

PRODUCT OVERVIEW

Crack repair technology includes two categories:

1.Surface sealing and filling to prevent steel erosion.

2.Restoring concrete strength by using pressure grouting or injection method. It can be applied to all cracks, small or large. The treatment can significantly improve the concrete strength and durability.

3.Bond Materials crack repair and reinforcement products can be used to effectively repair the cracks and improve the overall carrying capacity of concrete structures.

It has the following main characteristics:

■ Eco-friendly products, construction safe and reliable

■ Strong adhesion, excellent crack sealing property.

■ Strong penetration, low viscosity, can be injected into small cracks.

■ High toughness, anti-aging, anti-acid, anti-alkali and anti-corrosion

■ No shrinkage when hardened, good durability.

APPLICATIONS

CoolBond® EP-318 are two-component adhesives made from asphalt-modified epoxy. They have the characteristics of both epoxy and asphalt. It has excellent outdoor performance such as waterproof, anti-aging and anti-corrosion. The EP-318 is an epoxy asphalt mastic for various repair and bonding applications. It is non-flowing, easy-to-spread, suitable for a variety of engineering materials such as metal, concrete, stone, brick, etc. The product can be widely used in building construction repair and bonding. It can also be designed for functional pavement, repair and leveling of road surfaces.

PRODUCT

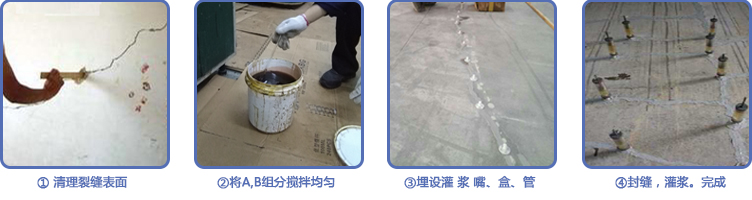

APPLICATION GUIDE

1. Add product A to curing agent B into a container and mix thoroughly.

2. Clean the designated area thoroughly, removing the floating pulp skin, loose objects, dust, grease, etc..

3. Only apply to the dry and clean surfaces at temperature above 5 ℃;

4. The first three guns must be abandoned.

5. Do not spray water on the surface within 4 hours of application.

TECHNICAL PARAMETERS

| Product Name | EP-318 |

| Mix Ratio A:B (weight) | A:B=2:1 |

| Mixture Appearance | Black viscous liquid |

| Mixture Density | 1.3 |

| Application Time (25ºC, min) | 30-40 |

| Initial Curing Time (25ºC, hours) | 1.5 |

| Curing Time (25ºC, hours) | 24 |

| Hardness (Shore D) | Comply with concrete structural re-enforcement standard GB50367 |

APPLICATION CASES

CRACK REPAIR ADHESIVE

PRODUCT OVERVIEW

Crack repair technology includes two categories:

1.Surface sealing and filling to prevent steel erosion.

2.Restoring concrete strength by using pressure grouting or injection method. It can be applied to all cracks, small or large. The treatment can significantly improve the concrete strength and durability.

3.Bond Materials crack repair and reinforcement products can be used to effectively repair the cracks and improve the overall carrying capacity of concrete structures.

It has the following main characteristics:

■ Eco-friendly products, construction safe and reliable

■ Strong adhesion, excellent crack sealing property.

■ Strong penetration, low viscosity, can be injected into small cracks.

■ High toughness, anti-aging, anti-acid, anti-alkali and anti-corrosion

■ No shrinkage when hardened, good durability.

APPLICATIONS

CoolBond® EP-318 are two-component adhesives made from asphalt-modified epoxy. They have the characteristics of both epoxy and asphalt. It has excellent outdoor performance such as waterproof, anti-aging and anti-corrosion. The EP-318 is an epoxy asphalt mastic for various repair and bonding applications. It is non-flowing, easy-to-spread, suitable for a variety of engineering materials such as metal, concrete, stone, brick, etc. The product can be widely used in building construction repair and bonding. It can also be designed for functional pavement, repair and leveling of road surfaces.

PRODUCT

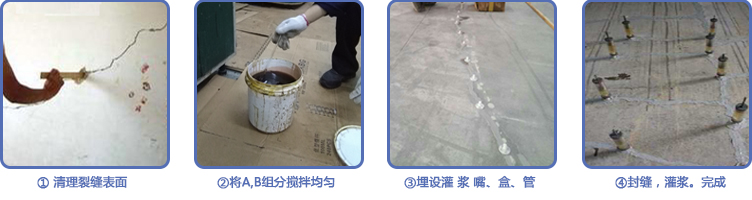

APPLICATION GUIDE

1. Add product A to curing agent B into a container and mix thoroughly.

2. Clean the designated area thoroughly, removing the floating pulp skin, loose objects, dust, grease, etc..

3. Only apply to the dry and clean surfaces at temperature above 5 ℃;

4. The first three guns must be abandoned.

5. Do not spray water on the surface within 4 hours of application.

TECHNICAL PARAMETERS

| Product Name | EP-318 |

| Mix Ratio A:B (weight) | A:B=2:1 |

| Mixture Appearance | Black viscous liquid |

| Mixture Density | 1.3 |

| Application Time (25ºC, min) | 30-40 |

| Initial Curing Time (25ºC, hours) | 1.5 |

| Curing Time (25ºC, hours) | 24 |

| Hardness (Shore D) | Comply with concrete structural re-enforcement standard GB50367 |

APPLICATION CASES

Service Hotline:400 825 1528

Phone:+86-20-82210601

Fax:+86-20-82210626

Mailbox:sales@gzthebond.com