ADHESIVES FOR STEEL BAR AND REBAR PLANTING

PRODUCT OVERVIEW

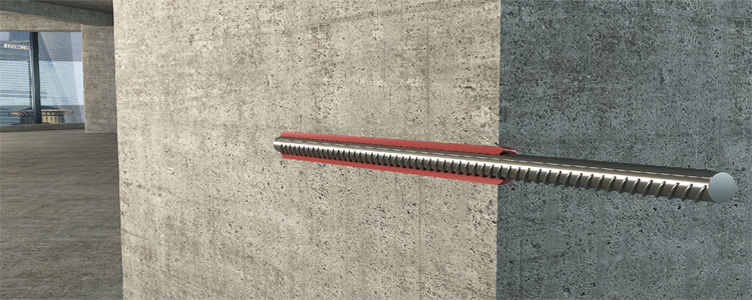

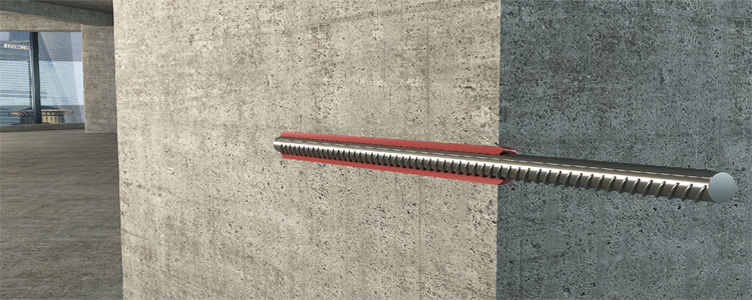

A reinforcing bar is is commonly used in building construction to strengthen load bearing structures. A ribbed or barbed steel bar is inserted into a concrete, rock or other substrate pre-drilled hole where it is secured with a high strength adhesive. The Bond Chemicals supplies high-strength, high cohesive force adhesives for such applications. It has the following main characteristics:

■ Eco-friendly, construction safe and reliable.

■ High strength, strong adhesion, toughness, equivalent to pre-embedded materials

■ Good heat resistance, no creep at ambient temperature.

■ Modified epoxy resin, anti-acid, anti-alkali, anti-aging, resistant to UV.

■ Good Thixotropy especially for side or top anchorage.

APPLICATIONS

CoolBond® Epoxy is a two-component outdoor epoxy series developed by The Bond Materials (Guangzhou) Co. Ltd and Bongding Technology Australia (BTA) Pty Ltd.. It has excellent outdoor weather, acid and alkali resistant properties. CoolBond® EP-238 is a multi-purpose epoxy adhesive mainly used for bonding various structural engineering materials such as metal, concrete, stone, brick and a variety of hard plastics, ideally for outdoor cement concrete bonding and anchoring for road, bridges constructions.

PRODUCTS

APPLICATION GUIDE

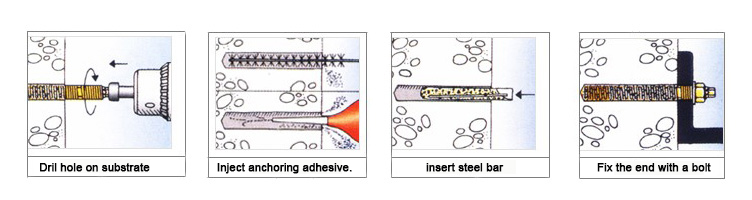

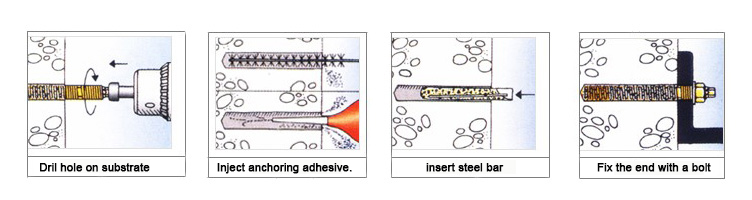

1. Drill a hole on the substrates eg. concrete, wall rock and etc.

2. Clean the designated area, removing the loose dust.

3. Inject high-strength Coolbond anchoring adhesive.

4. Insert steel bar.

5. Fix the end of steel bar with a bolt.

Note:

1. Only apply to the dry and clean surfaces at temperature above 5 ℃.

2. Do not spray water on the surface within 4 hours of application.

3. Do not shift the application objects before curing.

TECHNICAL PARAMETERS

| Product Name | Appearance | Mix Ratio A:B RATIO | Viscosity (25ºC, CPS) | Curing Time (25ºC, min) | Initial Curing Time (25ºC, hour) |

Hardness (Shore D) |

| EP-238A | Light yellow | 1:1 | 80000-10000 | 30 - 40 min | 2.5h | D65-70 |

| EP-238B | Brownish Yellow | 1:1 | 60000-80000 | 30 - 40 min | 2.5h | D65-70 |

| Mix Ratio A:B (weight ratio) | A:B=1:1 | |||||

| Mixture Appearance | Black or gray viscous liquid | |||||

| Mixture Density | 1.6 | |||||

| Application Time (25ºC, min) | 40-60 | |||||

| Initial Curing Time (25ºC, hours) | 2 | |||||

| Curing Time (25ºC, hours) | 24 | |||||

| Hardness (Shore D) | Comply with concrete structural re-enforcement standard GB50367 | |||||

ADHESIVES FOR STEEL BAR AND REBAR PLANTING

PRODUCT OVERVIEW

A reinforcing bar is is commonly used in building construction to strengthen load bearing structures. A ribbed or barbed steel bar is inserted into a concrete, rock or other substrate pre-drilled hole where it is secured with a high strength adhesive. The Bond Chemicals supplies high-strength, high cohesive force adhesives for such applications. It has the following main characteristics:

■ Eco-friendly, construction safe and reliable.

■ High strength, strong adhesion, toughness, equivalent to pre-embedded materials

■ Good heat resistance, no creep at ambient temperature.

■ Modified epoxy resin, anti-acid, anti-alkali, anti-aging, resistant to UV.

■ Good Thixotropy especially for side or top anchorage.

APPLICATIONS

CoolBond® Epoxy is a two-component outdoor epoxy series developed by The Bond Materials (Guangzhou) Co. Ltd and Bongding Technology Australia (BTA) Pty Ltd.. It has excellent outdoor weather, acid and alkali resistant properties. CoolBond® EP-238 is a multi-purpose epoxy adhesive mainly used for bonding various structural engineering materials such as metal, concrete, stone, brick and a variety of hard plastics, ideally for outdoor cement concrete bonding and anchoring for road, bridges constructions.

PRODUCTS

APPLICATION GUIDE

1. Drill a hole on the substrates eg. concrete, wall rock and etc.

2. Clean the designated area, removing the loose dust.

3. Inject high-strength Coolbond anchoring adhesive.

4. Insert steel bar.

5. Fix the end of steel bar with a bolt.

Note:

1. Only apply to the dry and clean surfaces at temperature above 5 ℃.

2. Do not spray water on the surface within 4 hours of application.

3. Do not shift the application objects before curing.

TECHNICAL PARAMETERS

| Product Name | Appearance | Mix Ratio A:B RATIO | Viscosity (25ºC, CPS) | Curing Time (25ºC, min) | Initial Curing Time (25ºC, hour) |

Hardness (Shore D) |

| EP-238A | Light yellow | 1:1 | 80000-10000 | 30 - 40 min | 2.5h | D65-70 |

| EP-238B | Brownish Yellow | 1:1 | 60000-80000 | 30 - 40 min | 2.5h | D65-70 |

| Mix Ratio A:B (weight ratio) | A:B=1:1 | |||||

| Mixture Appearance | Black or gray viscous liquid | |||||

| Mixture Density | 1.6 | |||||

| Application Time (25ºC, min) | 40-60 | |||||

| Initial Curing Time (25ºC, hours) | 2 | |||||

| Curing Time (25ºC, hours) | 24 | |||||

| Hardness (Shore D) | Comply with concrete structural re-enforcement standard GB50367 | |||||

Service Hotline:400 825 1528

Phone:+86-20-82210601

Fax:+86-20-82210626

Mailbox:sales@gzthebond.com