With the rapid development of the label industry, self-adhesive labels are more and more widely used in various product packaging fields. Because people have higher and higher requirements for external packaging, the use of high-quality labels will enhance the delicateness of packaging. Increase the value of goods.

Film labels are a type of self-adhesive labels. They are usually printed with various patterns and texts on their surface, and are mainly used for advertising, variety identification, information prompting and decoration.

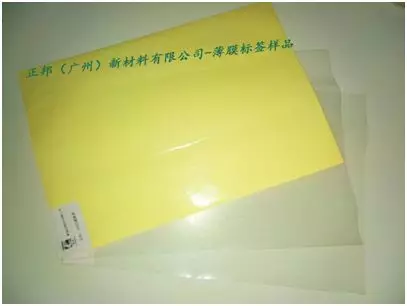

The structure of the film adhesive material is composed of three parts: surface material, adhesive and bottom paper.

①. Surface material: the surface material, which is the material that accepts printed graphics on the front and adhesive on the back, and is finally applied to the adhered object. In order to be able to adapt to printing and printing, the surface material must have good inking properties and have sufficient strength so that it will not be damaged in various processing processes, such as die cutting, waste disposal, slitting and labeling.

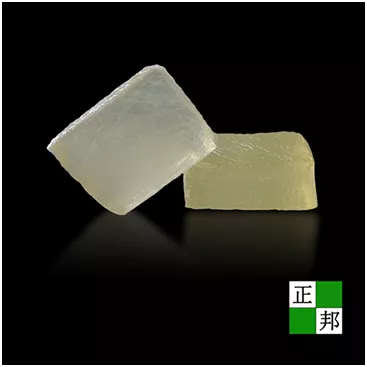

②. Adhesive: This is the most important part of the self-adhesive material technology and the key to the label application technology. Compared with water-based and oil-based adhesives, the hot-melt pressure-sensitive adhesive of Zhengbang New Materials has the characteristics of environmental protection, non-toxicity, fast coating speed and high production efficiency. From the perspective of environmental protection, zero-pollution hot-melt pressure-sensitive adhesives are film labels best choice.

③. Backing paper: The role of the backing paper is to accept the release agent coating, protect the adhesive on the back of the face material, and support the face material, so that it can be die-cut, waste discharged and labeled on the labeling machine.

Compared with paper labels, film stickers have many advantages, such as beautiful appearance, wear resistance, water resistance, corrosion resistance, not easy to be torn, good transparency, etc. The use of film stickers is the development trend of the label industry in recent years. Therefore, the application fields of film stickers are becoming more and more extensive, such as daily chemical, electronics, alcohol, food, medicine, health care products and other industries, can be seen everywhere. As we all know, labels are an important part of product packaging, high-quality labels help labels achieve their best performance on products, and film stickers can perfectly meet the requirements.

The requirements of high-quality labels on adhesives are even stricter. The hot melt pressure-sensitive adhesive of Zhengbang New Materials has been successfully applied in the field of film labels for more than ten years. Zhengbang New Materials has advanced experimental equipment and an experienced technical research and development team. According to the different needs of customers, we have developed hot melt pressure sensitive adhesives with different characteristics. Zhengbang New Materials has always won the trust and support of new and old customers with reasonable prices and strict quality control.